Manufacturing

F593 Manufacturing

The two most popular forms of F593 bolts sold, purchased, and manufactured on the marketplace are studs and hex bolts. The F593 specification also covers hex cap screws but they are far less common. The difference between a hex bolt and a hex cap screw is the cap screw has tighter dimensional tolerances.

The labor operations listed below are the steps to manufacture F593 studs and hex bolts.

Fully Threaded Studs

Studs are all thread rod that is measured from the last full thread on one end to the last full thread on the other end. Unless used as an anchor rod with epoxy, studs typically have nuts on each end.

Typically, studs are cut and chamfered from 12’ lengths of mass-produced all-thread rod. Mass-produced all thread rod is usually manufactured by taking pitch diameter round bar and running it through threading dies which manually displaces the steel forming the threads.

These rods are then sold to manufacturers who will cut the studs to the desired length, chamfer them, and stamp them with the required grade symbol per the specification.

- Cutting: The all-thread rod is typically cut to the desired length using a band saw.

- Chamfering: Chamfering is the process of creating a beveled end to the studs. This is done by removing the first thread which helps create an easy nut assembly and reduces the risk of thread damage.

- Stamping: The F593 specification calls for a unique head marking requirement depending on the alloy group and condition used.

Heavy Hex Bolts

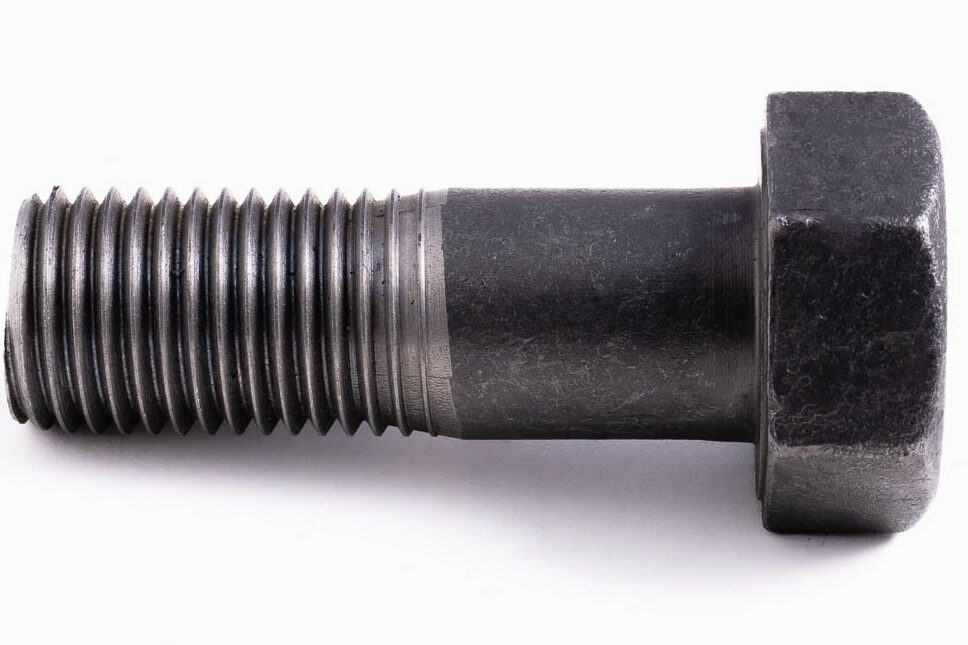

Hex bolts have a hexagonal head on one end with threads on the other end. Many times hex bolts and studs can both be used for the same applications, but an engineer should always be consulted in regard to any substitutions.

The process of manufacturing hex bolts goes as follows: the round bar is cut to length, headed, threaded, chamfered, solution annealed, mechanically tested, and intergranular tested.

Cutting: Steel round bar that is most commonly stocked at 20’ – 40’ is either sheared or saw cut to length.

Headed bolts are measured from the bottom of the head to the end of the threads, so extra steel is factored into the length which will be forged to form the head.

Heading: Hex heads are formed by heating one end of the steel and using an upsetter or hydraulic press to reshape the steel into the hex head. The head symbol is typically added to the head at this step.

Threading: Threads are either cut or rolled. Cut threading is the act of cutting the steel away to form the threads Roll threading is when the steel is displaced through pressure which creates the threads.

- Chamfering: Chamfering is a process in which the first thread is removed to facilitate nut assembly and protect the threads towards the end of the bolt.

- Solution Annealing: This is a heat-treating process that is performed on stainless steel in which the steel is heated to a specified temperature, held for a specified time, and cooled rapidly to ambient temperature. This process improves machinability and corrosion resistance.

- Mechanical Testing: Solution annealing can affect the mechanical properties of a headed bolt. Because of this, F593 bolts are further tested to guarantee that the bolts meet the minimum strength requirements per the specification.

- Intergranular testing: This final test which is conducted on the bolts evaluates if there is intergranular corrosion on the grain boundaries of the bolt as well as any surface impurities. This form of corrosion can significantly weaken the bolt.

- This test is performed by subjecting the bolt to various forms of corrosive environments and is then examined for any signs of impurities or corrosion.